In Context

The Challenge

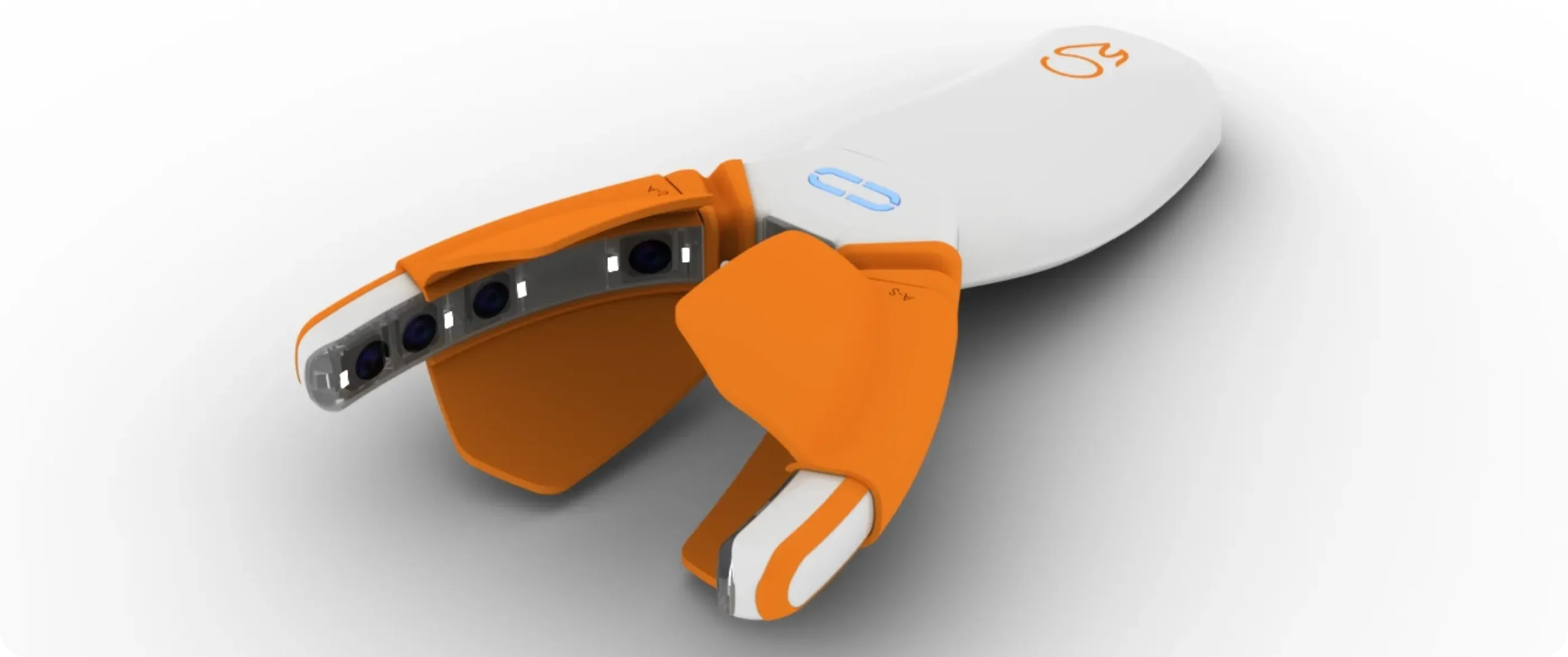

Smiletronix had a 3D printed concept when it selected Perdigó to design and develop the medical device.

Balancing the usability requirements of a small handheld device against relatively large, high-processing-power electronics, and flexible arms that fit in the mouth and extend outwards to obtain a good field of view for the cameras made the Smiletronix device a multidisciplinary challenge.

Perdigó's Approach

Usability, electronics, industrial design and mechanical engineers at Perdigó have conceived a 3-part device shell with enclosed leaf springs and electronics that meets Smiletronix’ brief.

Advanced prototyping and manufacturing techniques were required to make such a design viable, including ultrasonic welding, two-component (2k) injection moulding, and flexible electronics PCB designs.

Delivered Value

The elegantly simple concept integrating the flexible camera array and powerful embedded electronics into a handheld remote patient monitoring device has impressed even the most demanding stakeholders.

A functional prototype of the Smiletronix device has been designed and commissioned in record-time to meet tight timelines requested by the start-up’s lead investor.