In Context

Cell therapy is at the forefront of medical innovation, offering new hope for treating diseases such as cancer, autoimmune disorders, and genetic conditions.

As this sector grows, so does the demand for innovative and highly specialised equipment to support the manufacturing, delivery, and administration of these therapies.

Personalised immunotherapy, often employing CAR-T cells, is one of the most successful cell therapies to date, having successfully treated various forms of blood cancers. Some patients have experienced complete remission, showcasing the huge potential of this innovative treatment to transform cancer care.

The Challenge

Scaling up autologous cell therapies presents significant challenges: each therapy is custom-made from a patient’s own cells, requiring highly personalized and labour-intensive processes.

This complexity leads to high costs and logistical hurdles, such as ensuring consistent quality and managing the intricate supply chain.

Additionally, the need for specialised facilities and skilled personnel further complicates large-scale production, making widespread accessibility a daunting task.

Perdigó's Approach

Perdigó has partnered with the National Institute for Bioprocesses Research and Training (NIBRT) of Ireland to conceive a novel cell therapy system to democratise access to personalised cell therapies by revolutionising their manufacturing process in the clinical setting.

To break present barriers to large scale adoption of personalised cell therapy, the following value propositions are essential:

- Enhance production scale-up, bringing cost per treatment down;

- Enable production decentralisation and mass adoption at local treatment centres, removing current logistical barriers;

- Maximise both efficiency and treatment potency, facilitating the best health outcomes.

To achieve such ambitious goals for autologous, ex vivo cell therapies, the new cell therapy system is multiplexed in bottleneck production subprocesses.

Delivered Value

This project hinges on the multidisciplinary collaboration between Perdigó and the National Institute for Bioprocessing Research and Training (NIBRT).

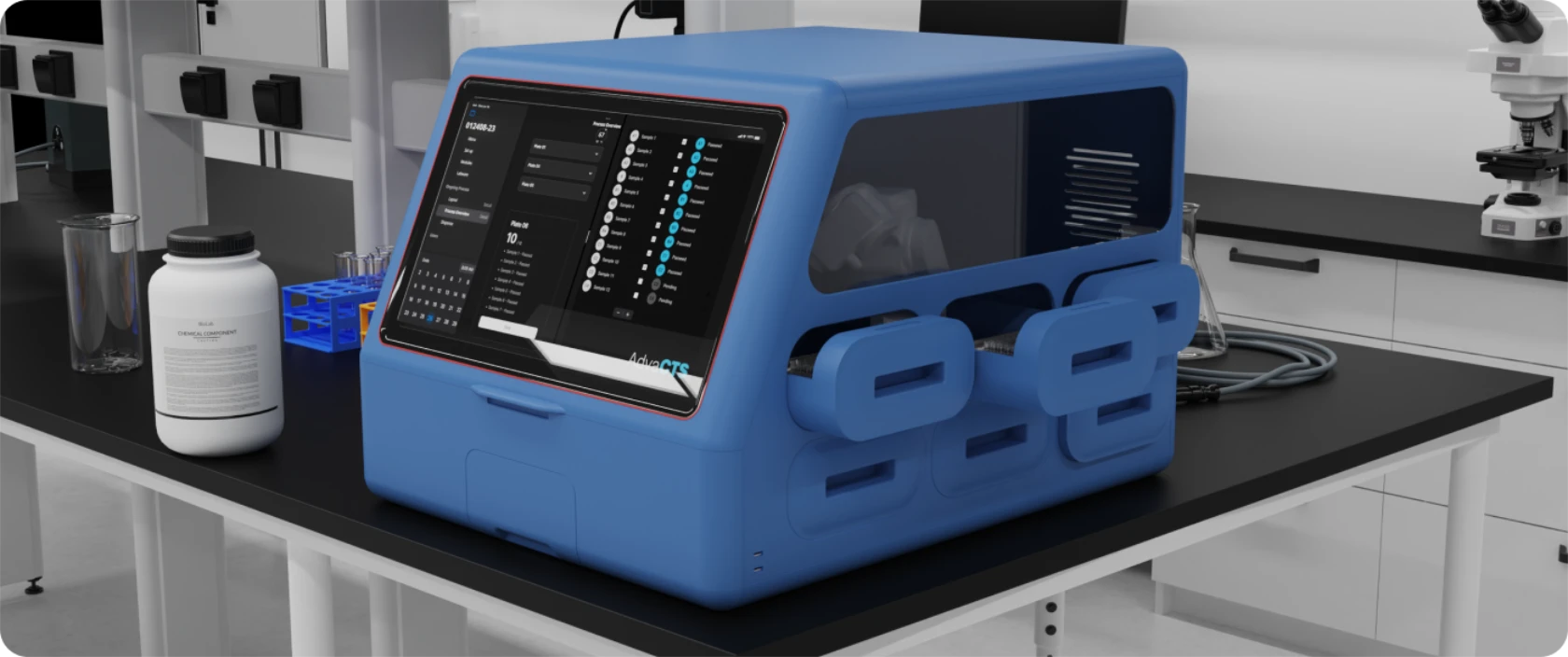

We take pride in having led the conceptualization phase of developing new this new piece of equipment for advanced cellular therapies, from idea to actionable design.

The delivered value mainly relies on transforming a visionary preliminar idea into a practical, high-impact conceptual solution, by identifying key design requirements, integrating cutting-edge technology, and ensuring compliance with stringent regulatory standards from the start, setting the stage for innovation in cellular therapy.

This proactive approach allows us to streamline development, reduce risks, and ensure that the final product is tailored for real-world clinical applications. We strongly believe that an advanced, end-to-end CTS platform is the missing piece of the puzzle—the one that will make personalised cell therapy a reality for most patients.